Marc Kegelaers & Kristof Van Hoecke

ADLC & SGS

‘The beauty of this project is its collaboration - an ecosystem involving AGLC, SGS, our client BASF, the city of Antwerp, and Port of Antwerp-Bruges - that enabled us to counter obstacles and to comply with legislation. It’s true innovation; no one has ever done this before.’

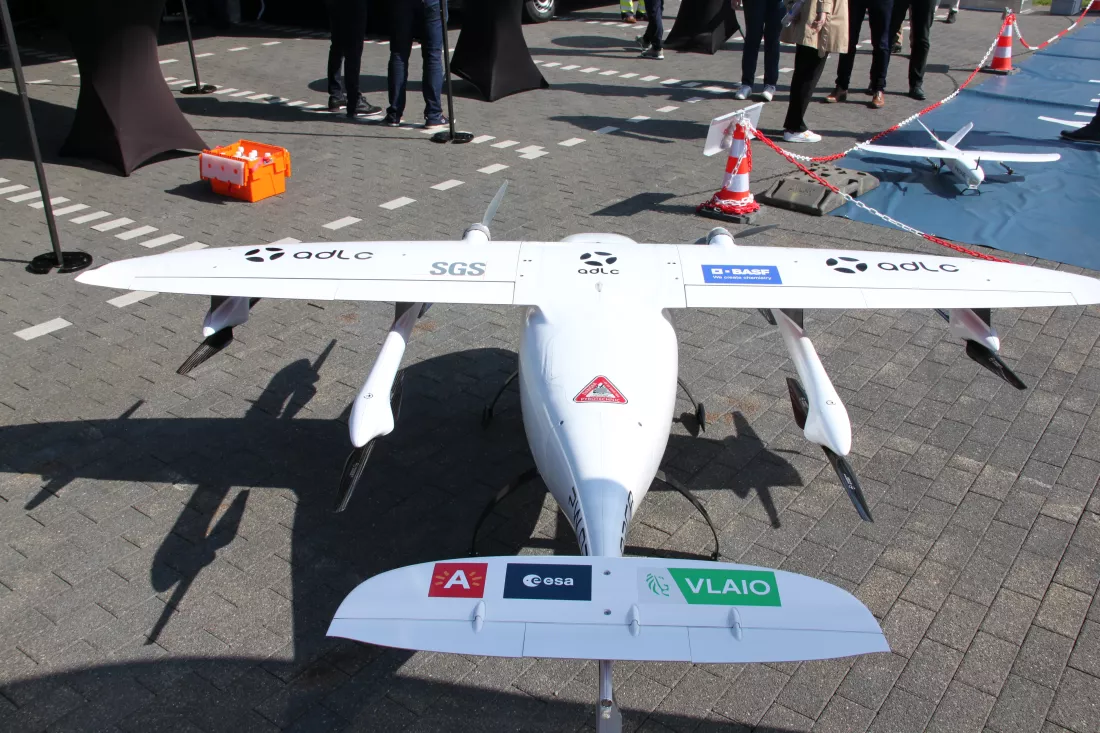

Samplifly: a groundbreaking drone project in the port of Antwerp

ADLC is an acronym for ‘A Drone Logistics Company’, a start-up rooted in The Beacon community. Specializing in urgent industrial deliveries by drone, ADLC aims to ensure a secure and sustainable service, seamlessly integrating drone transport into routine business operations.

To cover this project, ADLC partnered with SGS - the world’s leading testing, inspection, and certification company. Recognized as the benchmark for sustainability, quality, and integrity worldwide, SGS boasts a vast network of 98.000 employees operating across 2,650 offices and laboratories. The company actively contributes to building a better, safer, and more interconnected world.

The cooperation between ADLC and SGS resulted in a groundbreaking drone project, called Samplifly within the Port of Antwerp-Bruges. This project, which significantly impacts sample transportation efficiency, sustainability, and safety, aims to revolutionize traditional practices and is a milestone in using drones in an industrial environment.

Hello Marc, how did ADLC’s story begin?

Marc: ‘Vlerick Business School approached me to mentor two master-after-master students, Grégoire Moreau and Rayan Quintaes, who had developed a business plan for a drone-related company. Initially focusing on delivering consumer goods like pizzas, I redirected them towards finding a segment with more value, ultimately leading them to SGS.’

Kristof, how did you at SGS react?

Kristof: ‘It was the right call at the right time. We were exploring alternative ways to transport samples from the port to our labs, a process often time-consuming and not integrated into our operations. Drones presented a solution, enabling us to transport samples four times faster, significantly impacting efficiency and cost. In addition, this form of air transport reduces CO2 emissions by an impressive 80%.’

Marc, what kind of a drone does ADLC use?

Marc: ‘Our drone is relatively large, with a wingspan of 3 meters. It’s crash-resistant and electric, making it suitable for transporting dangerous goods in an industrial environment. With the support of the city of Antwerp, we could implement the solution faster than anticipated.’

Flying over numerous port companies sounds complex and highly regulated. How did you overcome the challenges?

Kristof: ‘The beauty of this project is its collaboration - an ecosystem involving ADLC, SGS, our client BASF, the city of Antwerp, and Port of Antwerp-Bruges - that enabled us to counter obstacles and to comply with legislation. It’s true innovation; no one has ever done this before.’

Marc: ‘Learning to master something difficult gives you a head start. Now that we’ve proven the concept, we can explore other locations and markets, such as transporting blood between hospitals or goods from seaports to drilling platforms. Legislation is a challenge, but it won’t stop us.’

What’s the significance of this project being based in Antwerp?

Marc: ‘It’s an Antwerp project with Antwerp technology. That’s enjoyable for everyone involved.’

Kristof: ‘Our goal is to globalize and expand the reach of this solution. After conducting some research, we identified at least 20 locations to implement successfully. Initially, we plan to roll out the project in two or three locations. Afterwards, we’ll explore additional opportunities. The insights gained from this Antwerp project are priceless.’

This article is based on the fifth episode of the podcast ‘The Story of Antwerp Innovators.'